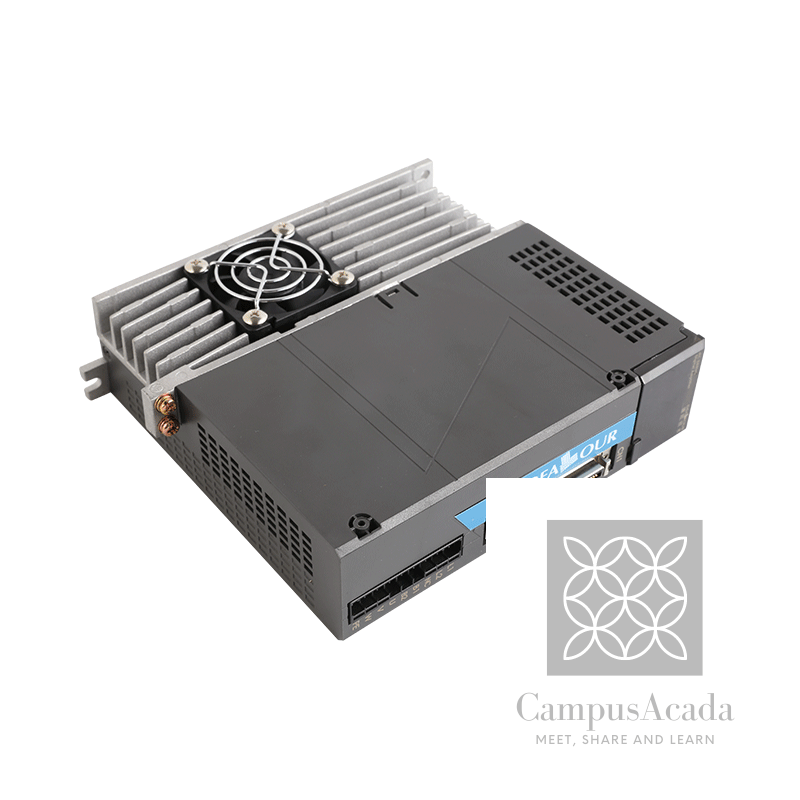

(https://www.servomotor-cn.com/product/standard-servo-driver/)In the realm of industrial automation, precise and efficient control of machinery and processes is essential for optimizing productivity and ensuring safety. This is where control motors come into play. Control motors are a type of electric motors that are specifically designed for precise control and regulation of speed, position, torque, and motion. With their advanced features and capabilities, control motors play a vital role in various industries, revolutionizing automation and enabling businesses to achieve new levels of efficiency and productivity. Product Features of Control Motors Control motors are characterized by a range of features that make them superior in applications where precise control and regulation are required.

Some of the key features of control motors include: High-Speed and Accuracy: Control motors are engineered to deliver high-speed operation without compromising on accuracy. They can achieve precise positioning and motion control, ensuring optimal performance in various applications. Variable Speed Control: Control motors offer the flexibility of variable speed control, allowing adjustments to be made according to specific application requirements. This feature enables smooth and precise operation, reducing wear and tear and extending the lifespan of the machinery. High Torque Output: Control motors are designed to provide high torque output, making them suitable for applications that require substantial power. This feature ensures efficient performance even in demanding tasks.

Compact and Lightweight Design: Control motors are built with a compact and lightweight design, making them easy to install and integrate into different systems. Their smaller footprint allows for space-saving installations, ideal for applications with limited space availability. Low Maintenance and Energy Efficiency: Control motors are known for their low maintenance requirements and energy efficiency. They are designed to operate with minimal downtime and feature advanced energy-saving technologies, reducing operational costs and environmental impact. Applications of Control Motors Control motors find extensive use across various industries and applications due to their precision control and versatile capabilities.

Some notable applications of control motors include: Robotics: Control motors are widely used in robotic systems for precise movement control. They enable robots to perform delicate and complex tasks with high accuracy, such as in assembly lines, material handling, and surgical procedures. CNC Machines: Control motors are essential components in computer numerical control (CNC) machines. They enable precise and controlled movement of the cutting tools, ensuring accurate machining operations in industries like automotive, aerospace, and manufacturing. Conveyor Systems: Control motors play a vital role in conveyor systems, ensuring smooth and accurate material handling. They enable precise positioning, speed control, and synchronization of conveyor belts, optimizing the efficiency of transportation processes in industries such as logistics, warehousing, and packaging.

Printing Machinery: Control motors are employed in printing machinery for precise control of printing processes. They enable accurate positioning and speed control of print heads, ensuring high-quality printing results in industries like graphic design, publishing, and packaging. Industrial Automation: Control motors are widely utilized in various automated systems, including factory automation, industrial machinery, and equipment. They provide precise control over movement, positioning, and speed, enabling efficient and reliable automation processes.

Conclusion Control motors have transformed industrial automation by offering precise and versatile control capabilities. With their advanced features and superior performance, control motors empower industries to achieve higher levels of efficiency, productivity, and accuracy. From robotics to CNC machines, conveyor systems to printing machinery, control motors have become indispensable in a wide range of applications. As technology continues to advance, control motors will undoubtedly continue to evolve, enabling even more sophisticated automation solutions in the future.

Some of the key features of control motors include: High-Speed and Accuracy: Control motors are engineered to deliver high-speed operation without compromising on accuracy. They can achieve precise positioning and motion control, ensuring optimal performance in various applications. Variable Speed Control: Control motors offer the flexibility of variable speed control, allowing adjustments to be made according to specific application requirements. This feature enables smooth and precise operation, reducing wear and tear and extending the lifespan of the machinery. High Torque Output: Control motors are designed to provide high torque output, making them suitable for applications that require substantial power. This feature ensures efficient performance even in demanding tasks.

Compact and Lightweight Design: Control motors are built with a compact and lightweight design, making them easy to install and integrate into different systems. Their smaller footprint allows for space-saving installations, ideal for applications with limited space availability. Low Maintenance and Energy Efficiency: Control motors are known for their low maintenance requirements and energy efficiency. They are designed to operate with minimal downtime and feature advanced energy-saving technologies, reducing operational costs and environmental impact. Applications of Control Motors Control motors find extensive use across various industries and applications due to their precision control and versatile capabilities.

Some notable applications of control motors include: Robotics: Control motors are widely used in robotic systems for precise movement control. They enable robots to perform delicate and complex tasks with high accuracy, such as in assembly lines, material handling, and surgical procedures. CNC Machines: Control motors are essential components in computer numerical control (CNC) machines. They enable precise and controlled movement of the cutting tools, ensuring accurate machining operations in industries like automotive, aerospace, and manufacturing. Conveyor Systems: Control motors play a vital role in conveyor systems, ensuring smooth and accurate material handling. They enable precise positioning, speed control, and synchronization of conveyor belts, optimizing the efficiency of transportation processes in industries such as logistics, warehousing, and packaging.

Printing Machinery: Control motors are employed in printing machinery for precise control of printing processes. They enable accurate positioning and speed control of print heads, ensuring high-quality printing results in industries like graphic design, publishing, and packaging. Industrial Automation: Control motors are widely utilized in various automated systems, including factory automation, industrial machinery, and equipment. They provide precise control over movement, positioning, and speed, enabling efficient and reliable automation processes.

Conclusion Control motors have transformed industrial automation by offering precise and versatile control capabilities. With their advanced features and superior performance, control motors empower industries to achieve higher levels of efficiency, productivity, and accuracy. From robotics to CNC machines, conveyor systems to printing machinery, control motors have become indispensable in a wide range of applications. As technology continues to advance, control motors will undoubtedly continue to evolve, enabling even more sophisticated automation solutions in the future.

(https://www.servomotor-cn.com/product/standard-servo-driver/)In the realm of industrial automation, precise and efficient control of machinery and processes is essential for optimizing productivity and ensuring safety. This is where control motors come into play. Control motors are a type of electric motors that are specifically designed for precise control and regulation of speed, position, torque, and motion. With their advanced features and capabilities, control motors play a vital role in various industries, revolutionizing automation and enabling businesses to achieve new levels of efficiency and productivity. Product Features of Control Motors Control motors are characterized by a range of features that make them superior in applications where precise control and regulation are required.

Some of the key features of control motors include: High-Speed and Accuracy: Control motors are engineered to deliver high-speed operation without compromising on accuracy. They can achieve precise positioning and motion control, ensuring optimal performance in various applications. Variable Speed Control: Control motors offer the flexibility of variable speed control, allowing adjustments to be made according to specific application requirements. This feature enables smooth and precise operation, reducing wear and tear and extending the lifespan of the machinery. High Torque Output: Control motors are designed to provide high torque output, making them suitable for applications that require substantial power. This feature ensures efficient performance even in demanding tasks.

Compact and Lightweight Design: Control motors are built with a compact and lightweight design, making them easy to install and integrate into different systems. Their smaller footprint allows for space-saving installations, ideal for applications with limited space availability. Low Maintenance and Energy Efficiency: Control motors are known for their low maintenance requirements and energy efficiency. They are designed to operate with minimal downtime and feature advanced energy-saving technologies, reducing operational costs and environmental impact. Applications of Control Motors Control motors find extensive use across various industries and applications due to their precision control and versatile capabilities.

Some notable applications of control motors include: Robotics: Control motors are widely used in robotic systems for precise movement control. They enable robots to perform delicate and complex tasks with high accuracy, such as in assembly lines, material handling, and surgical procedures. CNC Machines: Control motors are essential components in computer numerical control (CNC) machines. They enable precise and controlled movement of the cutting tools, ensuring accurate machining operations in industries like automotive, aerospace, and manufacturing. Conveyor Systems: Control motors play a vital role in conveyor systems, ensuring smooth and accurate material handling. They enable precise positioning, speed control, and synchronization of conveyor belts, optimizing the efficiency of transportation processes in industries such as logistics, warehousing, and packaging.

Printing Machinery: Control motors are employed in printing machinery for precise control of printing processes. They enable accurate positioning and speed control of print heads, ensuring high-quality printing results in industries like graphic design, publishing, and packaging. Industrial Automation: Control motors are widely utilized in various automated systems, including factory automation, industrial machinery, and equipment. They provide precise control over movement, positioning, and speed, enabling efficient and reliable automation processes.

Conclusion Control motors have transformed industrial automation by offering precise and versatile control capabilities. With their advanced features and superior performance, control motors empower industries to achieve higher levels of efficiency, productivity, and accuracy. From robotics to CNC machines, conveyor systems to printing machinery, control motors have become indispensable in a wide range of applications. As technology continues to advance, control motors will undoubtedly continue to evolve, enabling even more sophisticated automation solutions in the future.

0 Comments

0 Shares

2217 Views