-

Fil d’actualités

- EXPLORER

-

Pages

-

Groupes

-

Evènements

-

Blogs

-

Marketplace

-

Forums

-

Jeux

Best EX Inspection Software for Hazardous Areas – Simplify Compliance and Reporting

Managing hazardous area equipment can be complex and time-consuming, especially when it comes to ensuring compliance with stringent safety standards. Fortunately, with the rise of EX inspection software, companies now have a smarter and modern way to track, inspect, and manage their EX equipment register and hazardous equipment records. This digital transformation not only streamlines safety operations but also enhances productivity and regulatory compliance.

What is EX Inspection Software?

EX inspection software is a specialized digital tool designed for businesses that operate in potentially explosive environments. These platforms allow organizations to manage inspections, maintenance, and compliance activities related to EX (explosion-protected) equipment. Whether it’s used in oil & gas, mining, chemical processing, or any ATEX/IECEx-regulated industry, the software provides a centralized platform to record, update, and analyze inspection data efficiently.

Benefits of Using EX Inspection Software

1. Centralized Equipment Register

One of the main advantages of EX inspection software is the ability to create and manage a central database of all hazardous equipment. This eliminates the need for paper-based systems and spreadsheets, reducing the risk of data loss and duplication.

2. Streamlined Inspections

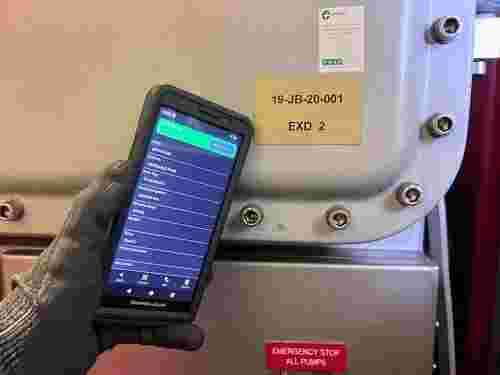

With preloaded checklists and compliance templates, technicians can perform inspections faster and more accurately. The software ensures every piece of equipment is reviewed against the relevant standards, and any defects or risks are logged immediately.

3. Real-Time Data and Reporting

EX inspection software allows real-time updates from the field, enabling immediate data capture through mobile devices or tablets. Reports can be generated instantly, helping managers make informed decisions and schedule corrective actions without delay.

4. Audit-Ready Documentation

Maintaining compliance with ATEX, IECEx, or OSHA regulations becomes easier when all documentation is stored digitally and kept up to date. The software can generate audit trails, logs, and certificates, ensuring your site is always ready for external inspections.

5. Predictive Maintenance and Risk Management

Advanced EX inspection platforms offer predictive maintenance features using historical inspection data. This helps identify patterns of wear, potential failures, and high-risk equipment, allowing for proactive risk management and better allocation of maintenance resources.

Why Modernize Your EX Equipment Management?

Traditional inspection methods are often prone to error, inefficiency, and delays. By switching to EX inspection software, companies can modernize their workflows, reduce downtime, and improve safety outcomes. Automated alerts, digital signatures, and GPS-tagged inspections ensure that every task is accounted for and aligned with global safety standards.

Choose the Right EX Inspection Software

When selecting EX inspection software, it’s important to consider features such as mobile compatibility, cloud storage, compliance with ATEX/IECEx regulations, and integration with existing CMMS or ERP systems. User-friendly interfaces, customizable templates, and strong data security should also be prioritized.

Conclusion

EX inspection software is transforming the way industries manage hazardous area equipment. It offers a smarter, faster, and more reliable approach to tracking and maintaining EX equipment registers. By embracing digital tools, businesses can boost compliance, reduce risk, and stay ahead in today’s safety-conscious industrial landscape.

- Whats New

- Shopping

- Wellness

- Sports

- Theater

- Religion

- Party

- Networking

- Music

- Literature

- Art

- Health

- Jeux

- Food

- Drinks

- Fitness

- Gardening

- Dance

- Causes

- Film

- Crafts

- Other/General

- Cricket

- Grooming

- Technology