-

Feed de notícias

- EXPLORAR

-

Páginas

-

Grupos

-

Eventos

-

Blogs

-

Marketplace

-

Fóruns

-

Jogos

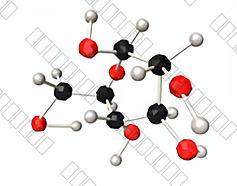

What reactions are required to produce raw materials for chemical suppliers of nifedipine?

Felodipine is a commonly used medication, belonging to the calcium ion antagonist class, used to treat cardiovascular diseases such as hypertension and coronary heart disease. However, in the pharmaceutical process, the raw materials of nifedipine need to undergo a series of reactions to obtain. This article will introduce the raw material reaction process required for the production of nifedipine. Let's learn about it together.

The raw materials for producing chemical suppliers of nifedipine mainly undergo the following key reaction steps:

1. Acylation reaction: The synthesis of nifedipine usually starts from raw materials of acyl chloride. An acylation reaction is the reaction of raw materials of an acyl chloride with corresponding alcohols to produce esterification products. In the preparation of nifedipine, an acylation reaction is used to react acyl chloride raw materials with specific alcohols to form the esterification intermediate of nifedipine.

2. Oxidation reaction: Based on esterification intermediates, they are converted into the final esterification product of chemical suppliers nifedipine through an oxidation reaction. Oxidation reactions typically use oxidants such as hydrogen peroxide or oxygen to oxidize specific functional groups in esterification intermediates to the desired functional groups in esterification end products.

3. Synthesis reaction: Based on the esterification final product, the final product of nifedipine is obtained through further synthesis reactions. Synthetic reactions typically involve multiple steps, including cyclization reactions, substitution reactions, etc., to construct the specific chemical structure of nifedipine.

4. Refining and Purification: After the reaction is complete, further refining and purification steps are required to remove impurities and impure substances, resulting in high-purity chemical suppliers of nifedipine raw materials. These steps may include solvent extraction, crystallization, filtration, and drying to ensure that the quality and purity of the final product meet the requirements.

In summary, the raw materials for producing chemical suppliers of nifedipine require key reaction steps such as acylation, oxidation, synthesis, refining, and purification. The efficiency and accuracy of these reaction processes are crucial for ensuring the quality and purity of nifedipine raw materials. Pharmaceutical companies need to strictly control reaction conditions and adopt appropriate process and technical measures in the production process to ensure a high-quality and stable supply of nifedipine.

- Whats New

- Shopping

- Wellness

- Sports

- Theater

- Religion

- Party

- Networking

- Music

- Literature

- Art

- Health

- Jogos

- Food

- Drinks

- Fitness

- Gardening

- Dance

- Causes

- Film

- Crafts

- Other/General

- Cricket

- Grooming

- Technology