Insights into the Growing Condition Monitoring System Market

According to Stratview Research, the condition monitoring system market was estimated at USD 2.7 billion in 2020 and is likely to grow at a CAGR of 4.3% during 2021-2027 to reach USD 3.6 billion in 2027.

In today's fast-paced industrial landscape, maximizing operational efficiency and minimizing downtime are paramount. This necessity has catalyzed the rapid growth of the condition monitoring system market. Condition monitoring systems offer real-time insights into the health and performance of machinery and equipment, enabling proactive maintenance and mitigating the risk of costly breakdowns. In this article, we delve into the burgeoning condition monitoring system market, exploring its growth drivers, key trends, and future prospects.

The Need for Predictive Maintenance: Historically, maintenance practices have been largely reactive, with equipment being repaired or replaced only after failure occurs. However, this approach is costly and disruptive, resulting in unplanned downtime, lost productivity, and increased maintenance expenses. To address these challenges, industries are increasingly adopting predictive maintenance strategies enabled by condition monitoring systems.

Condition monitoring systems utilize sensors, data analytics, and machine learning algorithms to continuously monitor equipment parameters such as temperature, vibration, pressure, and fluid levels. By analyzing this data in real time, condition monitoring systems can detect early signs of equipment degradation or impending failure, allowing maintenance teams to intervene proactively and perform repairs or replacements before critical issues arise.

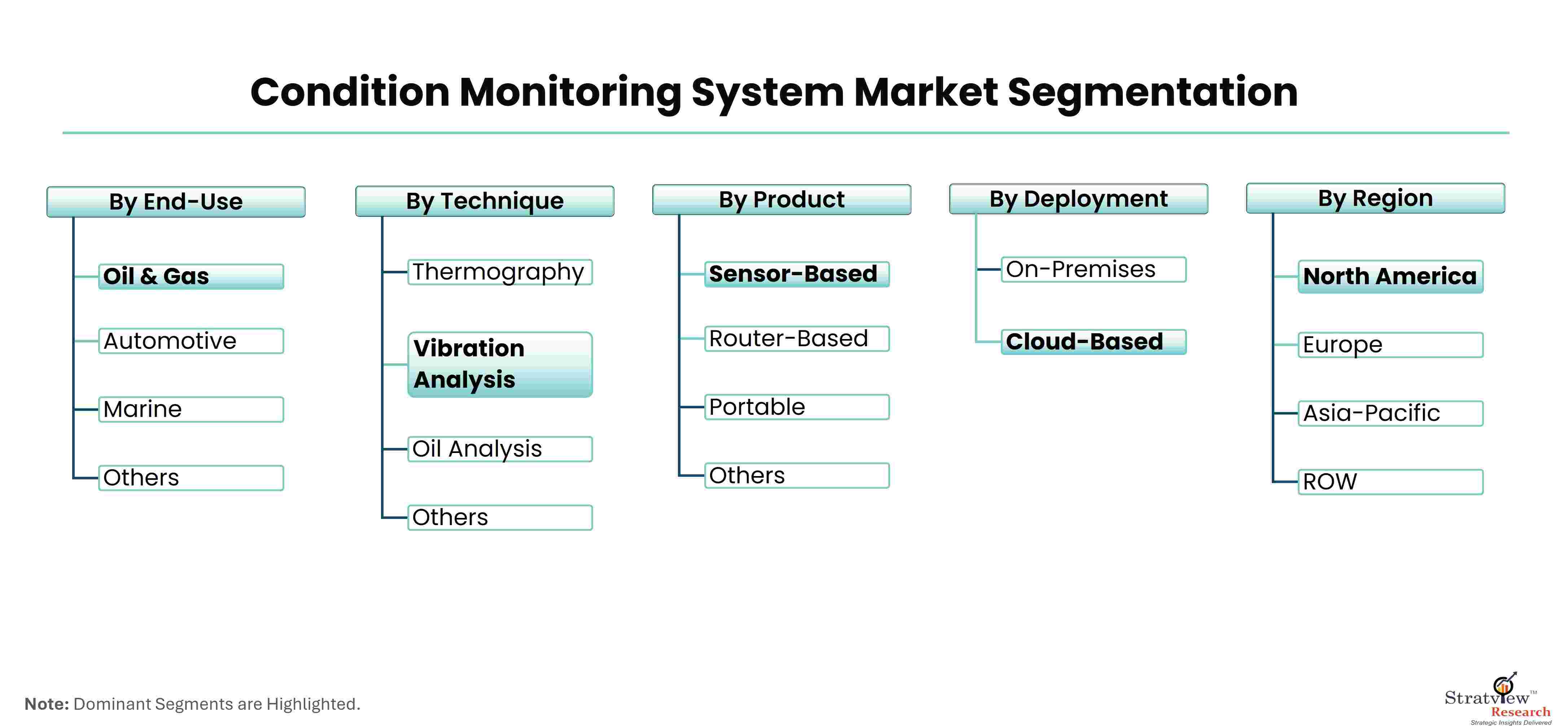

Market Drivers and Growth Factors: Several factors are driving the growth of the condition monitoring system market. Firstly, the increasing adoption of Industry 4.0 and smart manufacturing technologies is fueling demand for advanced monitoring and predictive maintenance solutions. Industries such as manufacturing, oil and gas, power generation, automotive, and aerospace are investing in digital transformation initiatives to optimize asset performance and reduce operational costs.

Additionally, the growing emphasis on equipment reliability, safety, and regulatory compliance is driving demand for condition monitoring systems. Industries operating in safety-critical environments, such as nuclear power plants and chemical processing facilities, rely on condition monitoring systems to ensure the integrity of their assets and prevent catastrophic failures that could have far-reaching consequences.

Moreover, advancements in sensor technology, wireless connectivity, cloud computing, and artificial intelligence are expanding the capabilities of condition monitoring systems and driving innovation in the market. Manufacturers are developing compact, low-cost sensors with enhanced sensitivity and accuracy, making condition monitoring systems more accessible to a wider range of industries and applications.

Key Trends in the Market: Several key trends are shaping the evolution of the condition monitoring system market. One notable trend is the integration of Industrial Internet of Things (IIoT) platforms with condition monitoring systems, enabling seamless data acquisition, analysis, and visualization across interconnected devices and systems. IIoT platforms facilitate remote monitoring and diagnostics, predictive analytics, and decision support, empowering maintenance teams to make data-driven decisions in real time.

Another trend is the emergence of cloud-based condition monitoring solutions, which offer scalability, flexibility, and accessibility advantages over traditional on-premises systems. Cloud-based platforms enable centralized data storage and analysis, real-time monitoring from anywhere with an internet connection, and integration with other enterprise systems such as asset management and enterprise resource planning (ERP) systems.

Furthermore, the adoption of predictive analytics and machine learning algorithms is revolutionizing condition monitoring practices, enabling predictive maintenance strategies that optimize asset performance and extend equipment lifespan. By analyzing historical data, identifying patterns, and predicting future failure events, predictive analytics algorithms help maintenance teams prioritize maintenance tasks, optimize resource allocation, and reduce downtime.

Future Prospects and Outlook: Looking ahead, the condition monitoring system market is poised for continued growth and innovation. As industries increasingly recognize the value proposition of predictive maintenance and digital transformation, demand for condition monitoring systems is expected to rise across verticals. Furthermore, advancements in sensor technology, data analytics, and connectivity will drive the development of more sophisticated and intelligent monitoring solutions capable of delivering actionable insights in real time.

Moreover, the proliferation of edge computing and edge analytics capabilities will enable condition monitoring systems to process and analyze data closer to the source, reducing latency, bandwidth requirements, and reliance on centralized infrastructure. Edge-enabled condition monitoring systems will be particularly beneficial for industries with remote or distributed assets, such as utilities, mining, and transportation.

In conclusion, the condition monitoring system market is experiencing rapid growth and transformation driven by the need for predictive maintenance, digitalization, and asset optimization. By leveraging advanced technologies such as IIoT, cloud computing, and predictive analytics, industries can enhance equipment reliability, maximize operational efficiency, and stay ahead of the competition in an increasingly competitive global marketplace. As the market continues to evolve, organizations that embrace innovation and invest in cutting-edge condition monitoring solutions will be best positioned to thrive in the digital age.

- Whats New

- Shopping

- Wellness

- Sports

- Theater

- Religion

- Party

- Networking

- Music

- Literature

- Art

- Health

- Games

- Food

- Drinks

- Fitness

- Gardening

- Dance

- Causes

- Film

- Crafts

- Other/General

- Cricket

- Grooming

- Technology