Introduction

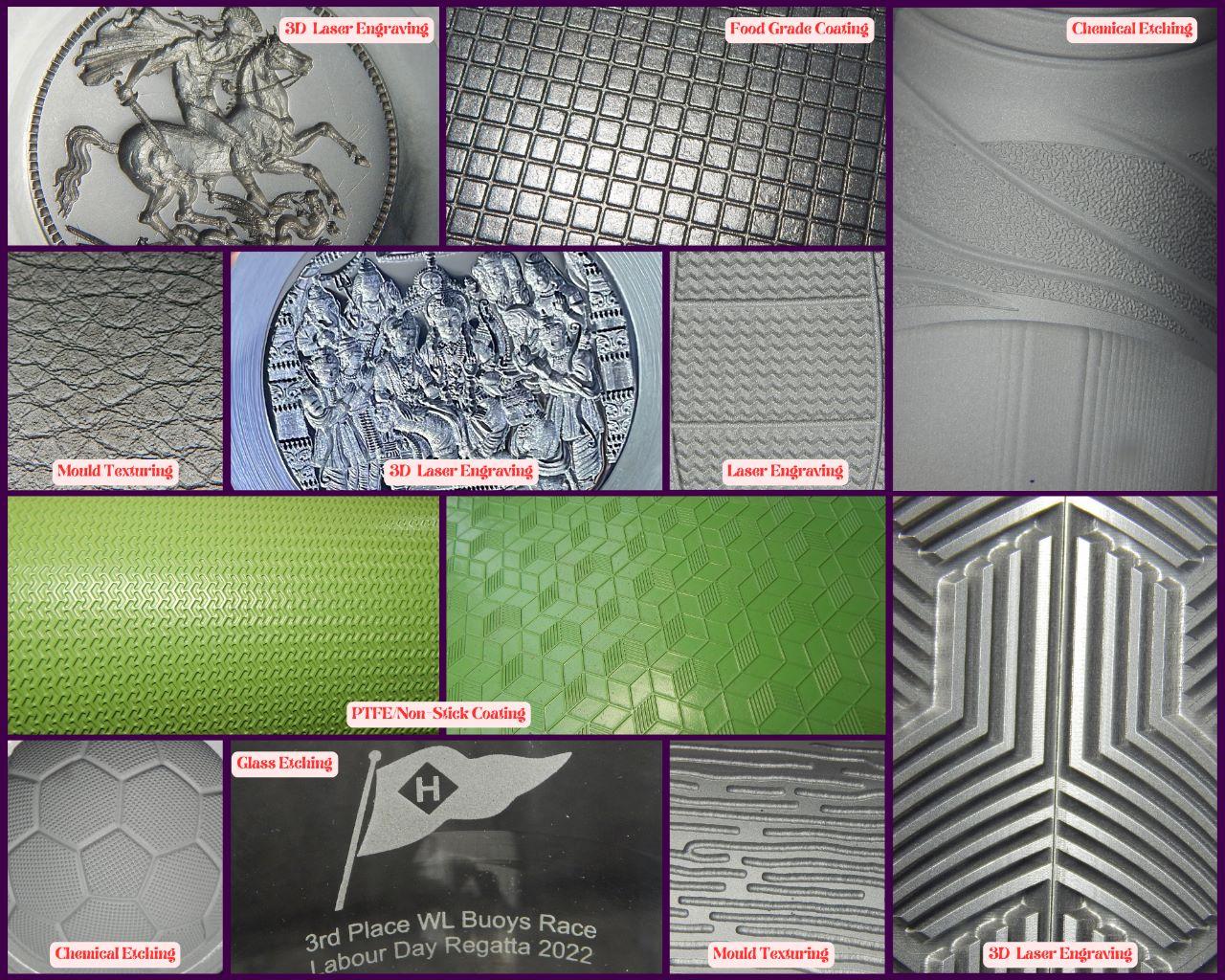

In the realm of surface treatment, PTFE (polytetrafluoroethylene) coating has become a go-to solution for enhancing performance and functionality across various industries. This blog post delves into the power of PTFE coating, its applications, and the potential synergies it holds with other surface treatment methods like 3D laser engraving and press plate etching. Join us as we unravel the remarkable benefits of PTFE coating and its transformative impact.

The Power of PTFE Coating

PTFE coating is a high-performance fluoropolymer coating that is widely recognized for its exceptional non-stick properties, chemical resistance, and low friction. These properties make it an invaluable solution for numerous applications, offering enhanced performance, durability, and efficiency.

Applications of PTFE Coating

- Industrial Machinery: PTFE coating plays a vital role in the industrial sector, particularly in machinery and equipment. By applying PTFE coating to components such as rollers, guides, and gears, friction and wear are significantly reduced. This results in smoother operation, extended lifespan, and reduced maintenance costs.

- Cookware and Bakeware: PTFE-coated cookware and bakeware have revolutionized the culinary world. The non-stick nature of the coating allows for easy food release, reducing the need for excessive oil or butter, and promoting healthier cooking. PTFE-coated pans and baking sheets also make cleaning a breeze.

- Automotive Components: PTFE coating finds applications in the automotive industry, improving the performance and longevity of various components. It is used on pistons, valves, bearings, and seals to reduce friction, enhance fuel efficiency, and minimize wear and tear. PTFE coating also provides corrosion resistance, extending the lifespan of automotive parts.

Synergies with Other Surface Treatment Methods

- 3D Laser Engraving: The combination of PTFE coating and 3D laser engraving offers a unique opportunity for creating visually captivating and functional designs. PTFE-coated surfaces can be precisely engraved using 3D laser technology, adding depth and texture to the coating. This opens up new possibilities for artistic expression and customization, making products stand out with both aesthetics and performance.

- Press Plate Etching: PTFE coating can complement press plate etching by enhancing the durability and functionality of the engraved designs. The non-stick properties of PTFE coating ensure that the engraved patterns on press plates release smoothly, improving the quality and longevity of the resulting imprints. This synergy allows for intricate and long-lasting designs on various surfaces, including laminates, paper, and fabrics.

PTFE Coating Services: The Key to Optimal Results

To fully leverage the power of PTFE coating, it is essential to collaborate with reputable PTFE coating services. These professionals possess the expertise, experience, and equipment required to ensure optimal coating quality and performance. They employ industry-leading techniques to apply the PTFE coating accurately, taking into account factors such as surface preparation, coating thickness, and curing processes.

By partnering with PTFE coating service providers, businesses and individuals can benefit from cost-effective solutions that enhance product performance, durability, and visual appeal.

Conclusion

PTFE coating is a game-changer in the realm of surface treatment, offering outstanding non-stick properties, chemical resistance, and low friction. Its applications span across industries, including machinery, cookware, and automotive components, among others. When combined with techniques like 3D laser engraving and press plate etching, PTFE coating unlocks new dimensions of functionality and aesthetics. By collaborating with reliable PTFE coating services, businesses can maximize the benefits of this transformative coating, ensuring optimal results and elevating product performance to new heights. Embrace the power of PTFE coating and experience the difference it can make in enhancing performance.