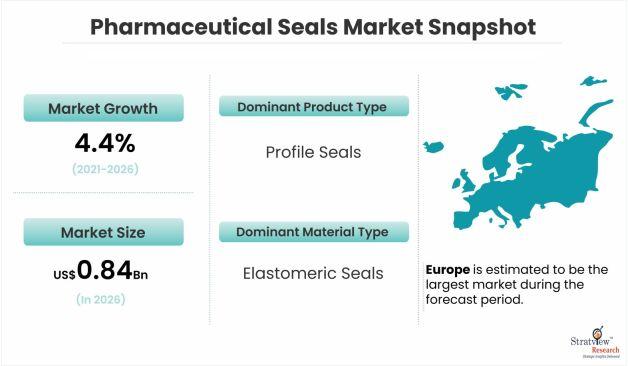

The Pharmaceutical Seals Market is segmented by Product Type (O-rings, Gaskets, Lip Seals, Profile Seals, and Others), Material Type (Elastomeric Seals, Thermoplastic Seals, and Metallic Seals), Motion Type (Static Seals, Linear Seals, and Rotary Seals), and Region (North America, Europe, Asia-Pacific, and the Rest of the World).

In the fast-paced world of pharmaceuticals, ensuring the safety and integrity of medications is of paramount importance. One crucial aspect often overlooked is the role of pharmaceutical seal technologies. These small yet mighty devices play a critical role in maintaining the efficacy and quality of pharmaceutical products. With recent advancements in seal technology, the industry is experiencing a game-changing shift toward enhanced protection and efficiency.

Pharmaceutical seals are typically used to secure drug containers, such as bottles, vials, or blister packs, preventing tampering and ensuring product integrity. Traditional seal technologies, such as induction seals or breakable caps, have served the industry well for many years. However, they have their limitations, including the potential for human error during application and the risk of tampering or counterfeiting.

The latest advancements in pharmaceutical seal technologies address these concerns and bring forth a new era of safety and efficiency. One notable development is the introduction of smart seals. These seals are equipped with advanced technologies such as RFID (Radio Frequency Identification) or NFC (Near Field Communication) tags, enabling real-time monitoring and tracking of products throughout the supply chain. This not only helps combat counterfeit drugs but also allows for better inventory management and improved patient safety.

Another groundbreaking advancement is the integration of tamper-evident features directly into the seal itself. These features provide visible signs of tampering, such as color change or irreversible damage, alerting healthcare providers and consumers to potential risks. This innovation greatly enhances the ability to detect and prevent the use of compromised medications, ensuring patient safety and building trust in the pharmaceutical industry.

Furthermore, advancements in seal materials have led to improved barrier properties, protecting medications from moisture, oxygen, and other environmental factors that could compromise their stability. This is particularly crucial for sensitive drugs, such as biologics or vaccines, which require stringent storage conditions. By enhancing the shelf life and efficacy of pharmaceutical products, these advancements contribute to reducing waste and increasing cost-effectiveness.

The pharmaceutical industry is also witnessing advancements in automated seal application processes. Robotic systems equipped with sophisticated vision systems and precise control mechanisms can ensure accurate and consistent sealing, minimizing human error and increasing production efficiency. This not only saves time and resources but also reduces the risk of product recalls or contamination due to improper sealing.

In conclusion, advancements in pharmaceutical seal technologies are revolutionizing the industry, offering enhanced safety, efficiency, and product integrity. The introduction of smart seals, tamper-evident features, improved barrier materials, and automated application processes are transforming the way medications are protected, tracked, and delivered. These innovations not only safeguard patient health but also streamline operations and build trust in the pharmaceutical supply chain. As the industry continues to embrace and integrate these advancements, we can expect to see a future where pharmaceutical seal technologies play an even more critical role in ensuring the safety and efficacy of medications worldwide.