-

Feed de Notícias

- EXPLORAR

-

Páginas

-

Grupos

-

Eventos

-

Blogs

-

Marketplace

-

Fóruns

-

Jogos

How Titanium Alloys Are Revolutionizing Aerospace Engineering

Titanium alloys are transforming the aerospace industry, driving innovations that enhance performance, efficiency, and safety. Their unique properties—such as exceptional strength-to-weight ratio, corrosion resistance, and high-temperature stability—make them indispensable in modern aerospace engineering. Here’s how titanium alloys are revolutionizing the field.

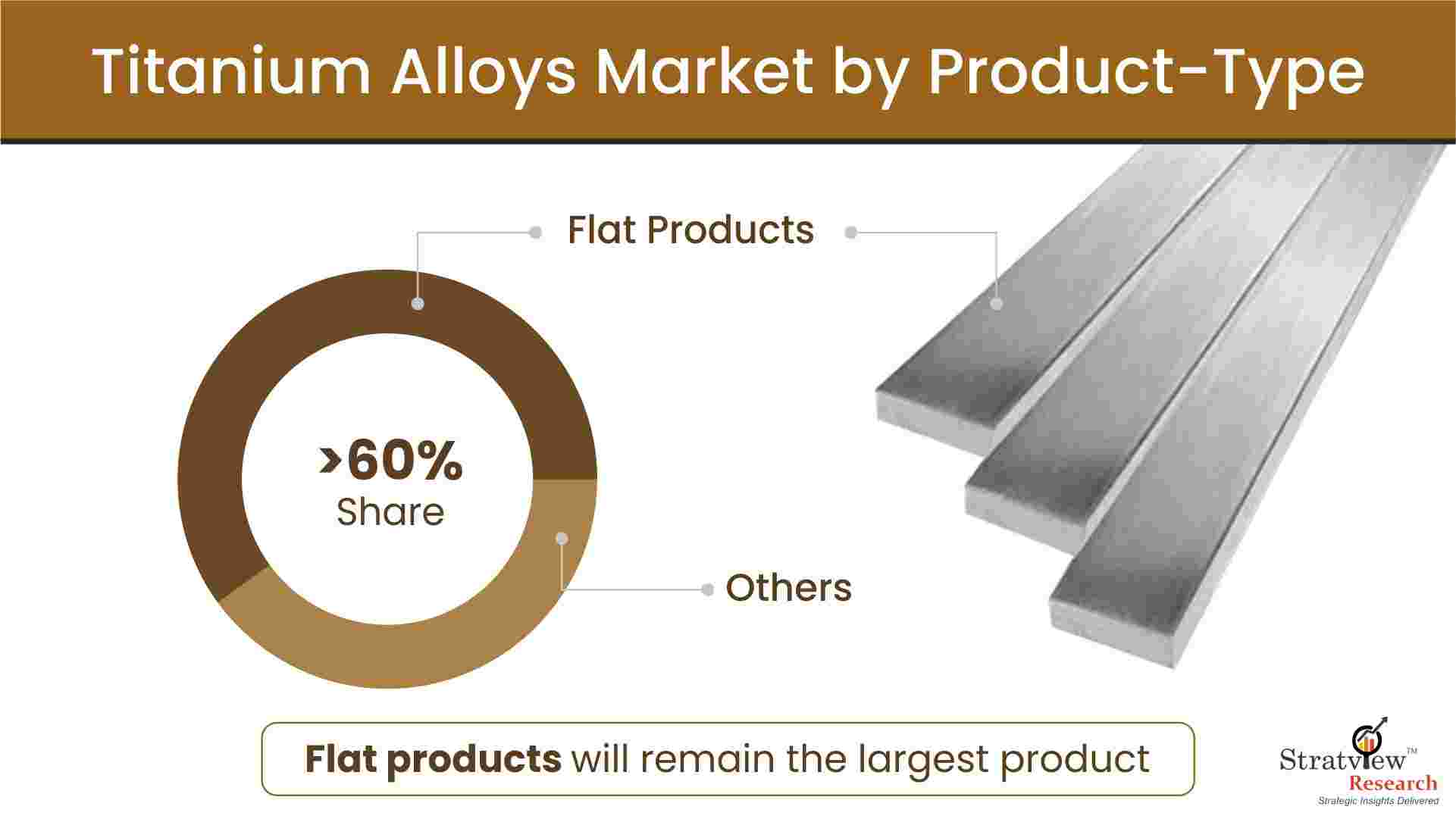

According to Stratview Research, the titanium alloys market is estimated to grow at a moderate CAGR of 4.9% during the forecast period to reach US$ 9 billion in 2028.

1. Enhancing Aircraft Performance

One of the most significant contributions of titanium alloys to aerospace engineering is their role in improving aircraft performance. The lightweight nature of titanium alloys reduces the overall weight of aircraft, which directly translates to improved fuel efficiency and greater payload capacity. By replacing heavier materials with titanium alloys in critical components such as landing gear, turbine blades, and structural elements, engineers can design more efficient and high-performing aircraft.

2. Increasing Durability and Reliability

Titanium alloys are renowned for their durability and resistance to extreme environmental conditions. They can withstand high temperatures and corrosive environments, making them ideal for use in components that experience significant thermal and mechanical stress. For example, titanium alloys are commonly used in jet engine components, such as compressor blades and turbine disks, where they endure high temperatures and pressures. Their resistance to corrosion ensures that these critical parts maintain their integrity and performance over time, reducing maintenance needs and enhancing reliability.

3. Enabling Advanced Aerospace Designs

The properties of titanium alloys facilitate the development of advanced aerospace designs that were previously impractical. Their high strength-to-weight ratio allows engineers to create complex geometries and intricate structures without compromising strength or performance. This capability is crucial for the development of next-generation aircraft and spacecraft, where innovative designs are necessary to meet evolving mission requirements and performance goals. Additionally, titanium alloys are increasingly used in space exploration, where their ability to perform in harsh environments is essential for the success of missions beyond Earth’s atmosphere.

4. Supporting the Transition to More Sustainable Technologies

As the aerospace industry aims to reduce its environmental footprint, titanium alloys play a key role in supporting more sustainable technologies. By improving fuel efficiency and reducing weight, titanium alloys contribute to lower emissions and reduced fuel consumption. Furthermore, advancements in recycling technologies and sustainable manufacturing processes for titanium alloys align with the industry’s broader goals of environmental responsibility and resource efficiency.

5. Driving Technological Advancements

The continuous evolution of titanium alloy technologies is pushing the boundaries of what is possible in aerospace engineering. Innovations in alloy compositions, processing techniques, and surface treatments are leading to the development of even more advanced materials with enhanced properties. These advancements are enabling the creation of high-performance components that meet the rigorous demands of modern aerospace applications.

In summary, titanium alloys are revolutionizing aerospace engineering by enhancing aircraft performance, increasing durability and reliability, enabling advanced designs, supporting sustainability, and driving technological advancements. As the aerospace industry continues to evolve, titanium alloys will remain at the forefront of innovation, contributing to the development of more efficient, reliable, and cutting-edge aerospace technologies.

- Whats New

- Shopping

- Wellness

- Sports

- Theater

- Religion

- Party

- Networking

- Music

- Literature

- Art

- Health

- Jogos

- Food

- Drinks

- Fitness

- Gardening

- Dance

- Causes

- Film

- Crafts

- Other/General

- Cricket

- Grooming

- Technology